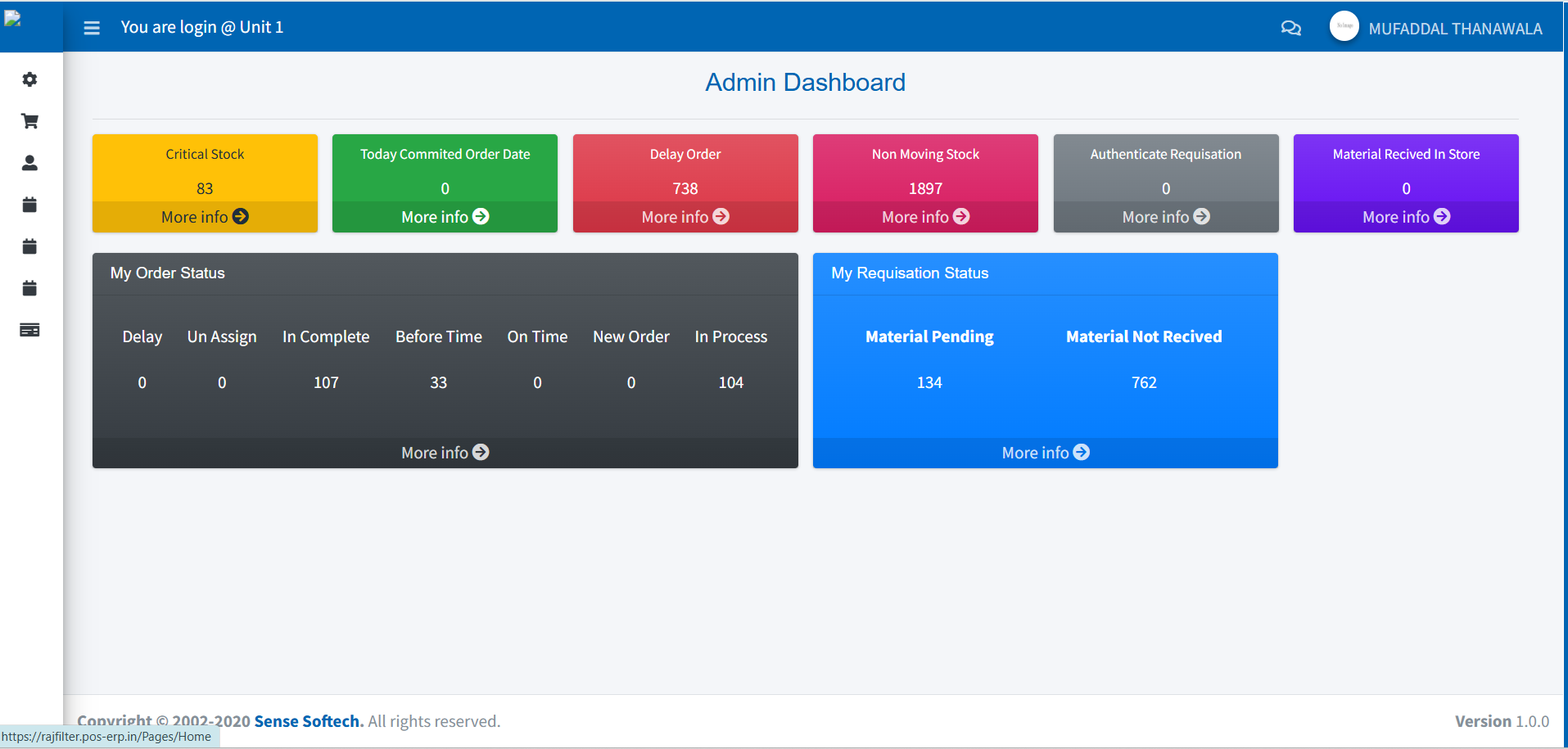

Why Choose Our Manufacturing ERP Development Services

Connected & Streamlined Operations:

Our custom-built Manufacturing ERP systems integrate seamlessly across departments—from production planning to inventory, procurement, and order management. Get real-time visibility, reduce operational bottlenecks, and boost manufacturing efficiency with a centralized platform tailored to your business.

- Automate and optimize production schedules to reduce downtime and maximize output.

- Track raw materials and finished goods in real time to maintain accurate stock levels.

- Connect departments like procurement, warehousing, and quality control for a smooth manufacturing cycle.

- Get actionable insights through dashboards and reports to improve efficiency and forecasting.

- Whether you're a small workshop or a large manufacturer, our ERP adapts to your needs as you grow

- Manage purchase orders, supplier relationships, and delivery timelines—all from one place.

- Automate repetitive tasks and reduce human error with smart ERP functionalities.

Our ERP solution isn’t just software—it’s a digital transformation tool that helps future-proof your manufacturing business. From shop floor to top floor, we help you stay lean, agile, and competitive.

Manufacturing ERP Development Process

Our structured software development approach ensures efficient, scalable, and high-quality solutions for your business.

Analysis

The development of a Manufacturing ERP system starts by understanding the business requirements and goals. We work closely with stakeholders to gather insights into the necessary features, performance targets, security considerations, and compliance standards.

A detailed Software Requirement Specification (SRS) document is then created, outlining all key aspects of the system to ensure clear direction and alignment before moving forward with development.

Process

The Manufacturing ERP development process starts with gathering business requirements and understanding the specific needs of stakeholders. A Software Requirement Specification (SRS) document is created to outline the system's features and objectives. The system is then designed, developed, and tested to meet the business goals and improve operational efficiency.

Planning

The planning phase of Manufacturing ERP development involves defining project goals, timelines, and resources. We collaborate with stakeholders to prioritize features and establish a clear roadmap. A detailed project plan is created to guide the development, ensuring alignment with business needs and efficient use of resources.

Design

The design phase of Manufacturing ERP development focuses on creating the system architecture and user interface. We define the overall structure, including data flow, integration points, and module design, ensuring scalability and ease of use. The design is reviewed with stakeholders to ensure it aligns with business requirements before moving to development.

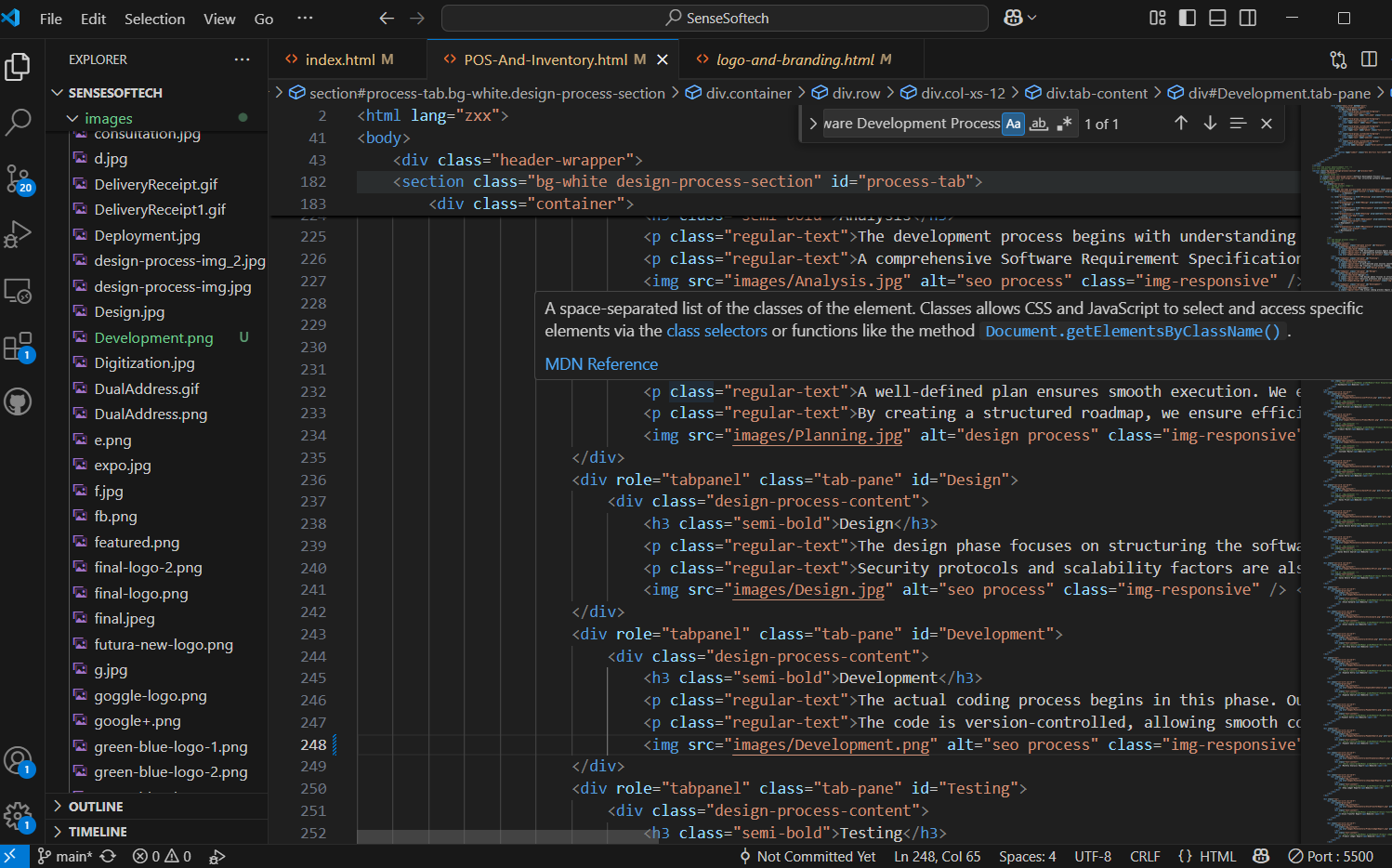

Development

The development phase of Manufacturing ERP involves building the system based on the approved design. Developers write code, configure modules, and integrate the ERP with existing systems to ensure smooth data flow. Continuous collaboration with stakeholders ensures that the system meets the defined requirements and business goals.

Testing

The testing phase of Manufacturing ERP development involves thoroughly evaluating the system for functionality, performance, and security. Various tests, including unit, integration, and user acceptance testing, are conducted to identify and fix any issues. The goal is to ensure the system meets all requirements and operates efficiently before deployment.

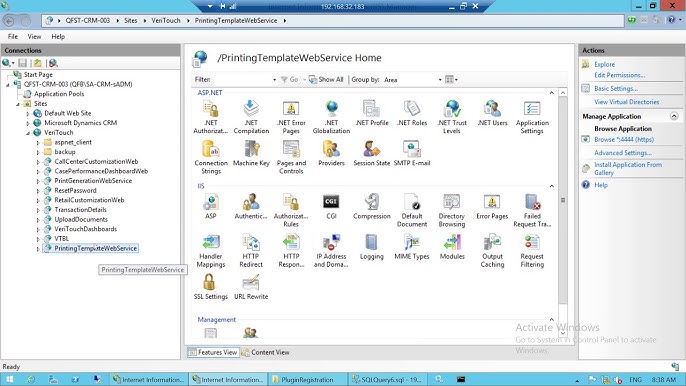

Deployment

The deployment phase of Manufacturing ERP involves rolling out the system to the live environment. This includes configuring the system, migrating data, and training users. Once the system is fully deployed, ongoing support and maintenance are provided to address any issues and ensure continued efficiency.

Updates

The updates phase of Manufacturing ERP involves regularly improving and enhancing the system to meet evolving business needs. This includes adding new features, improving functionality, and ensuring compatibility with other systems. Updates are tested and deployed to ensure the ERP remains efficient, secure, and aligned with industry standards.

Training

The training phase of Manufacturing ERP focuses on educating users on how to effectively use the system. Training sessions are tailored to different roles, ensuring that employees are familiar with the ERP's features and workflows. This helps maximize system adoption, improve efficiency, and reduce errors in daily operations.

Maintenance

The maintenance phase of Manufacturing ERP involves providing ongoing support to ensure the system remains functional and up to date. This includes monitoring performance, fixing bugs, applying security patches, and making necessary improvements. Regular maintenance ensures the ERP system continues to meet business needs and adapt to changes over time.

Featured Designs

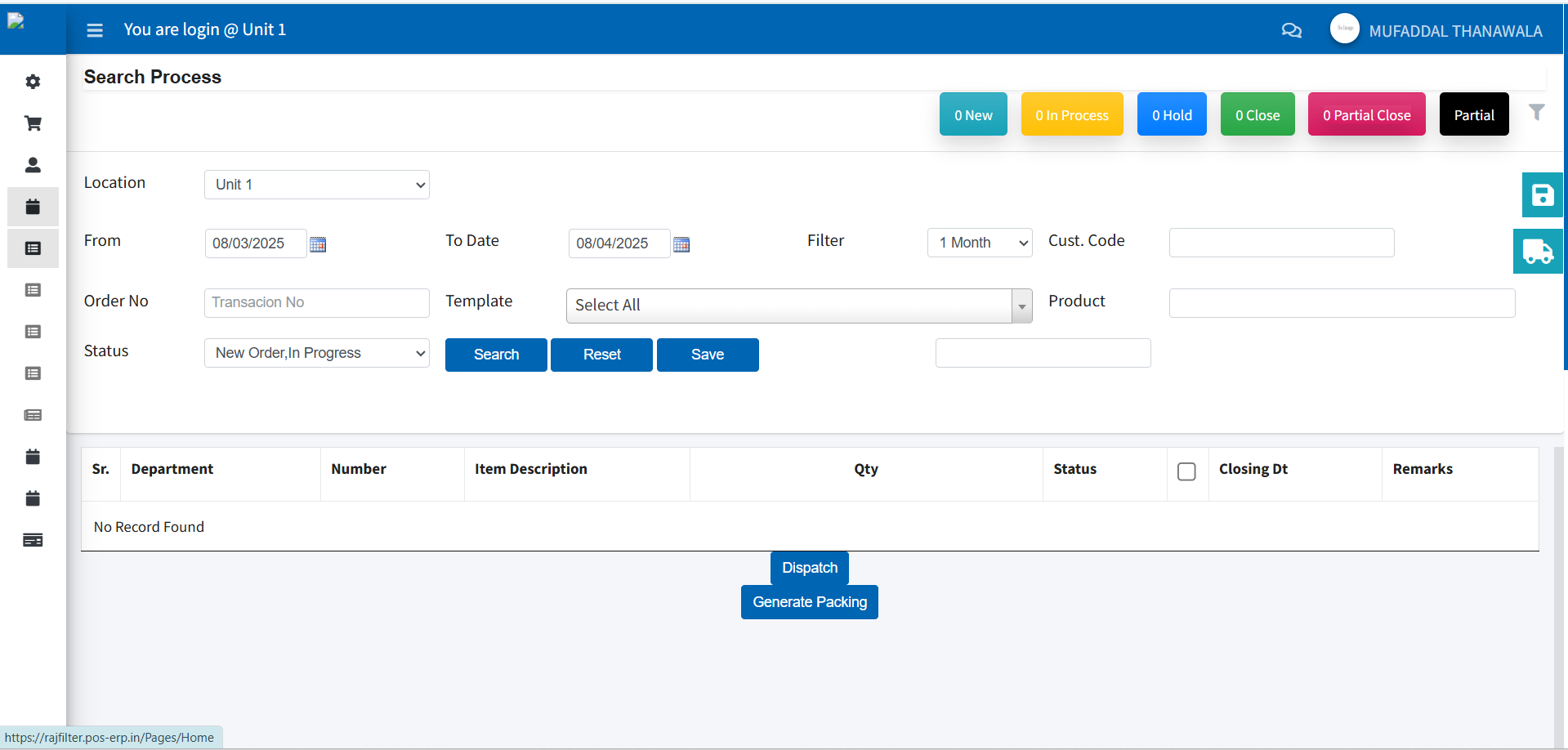

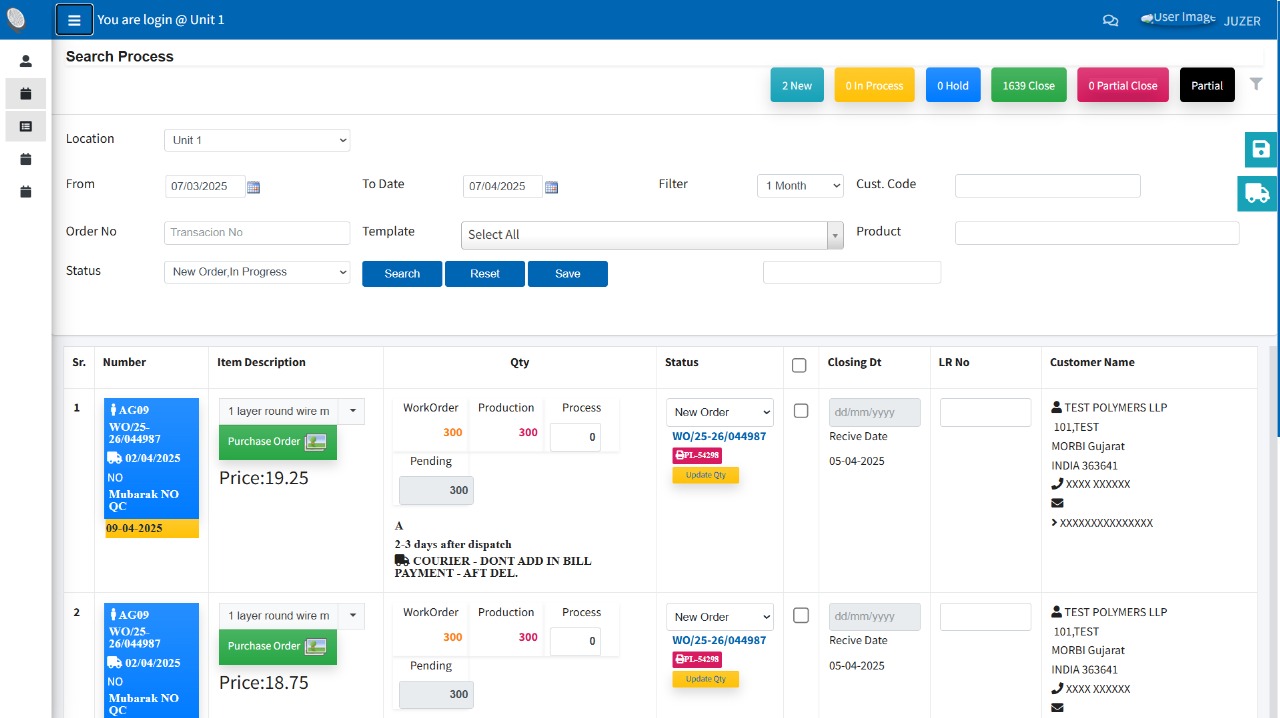

Sales Order ProcessERP

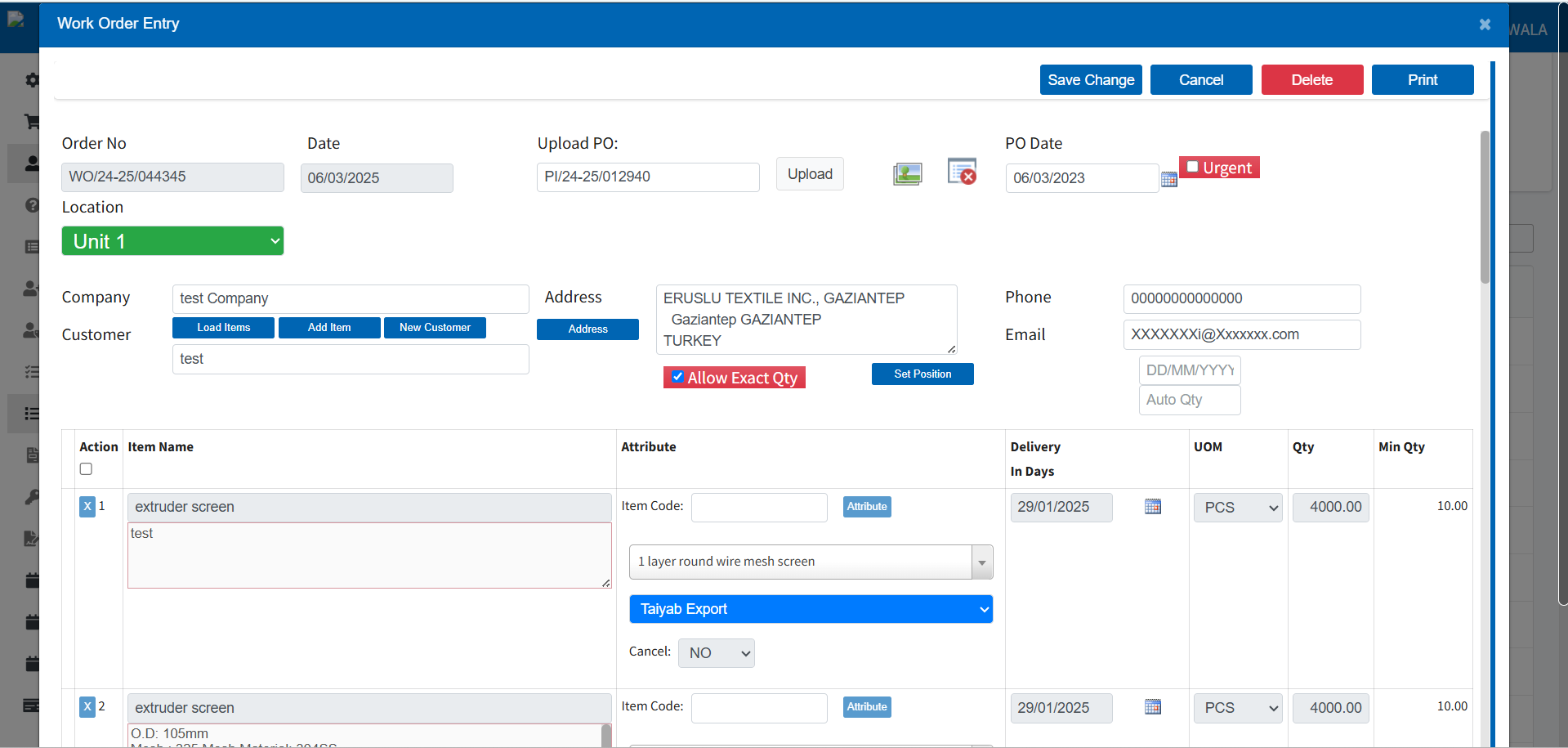

Work Order EntryERP

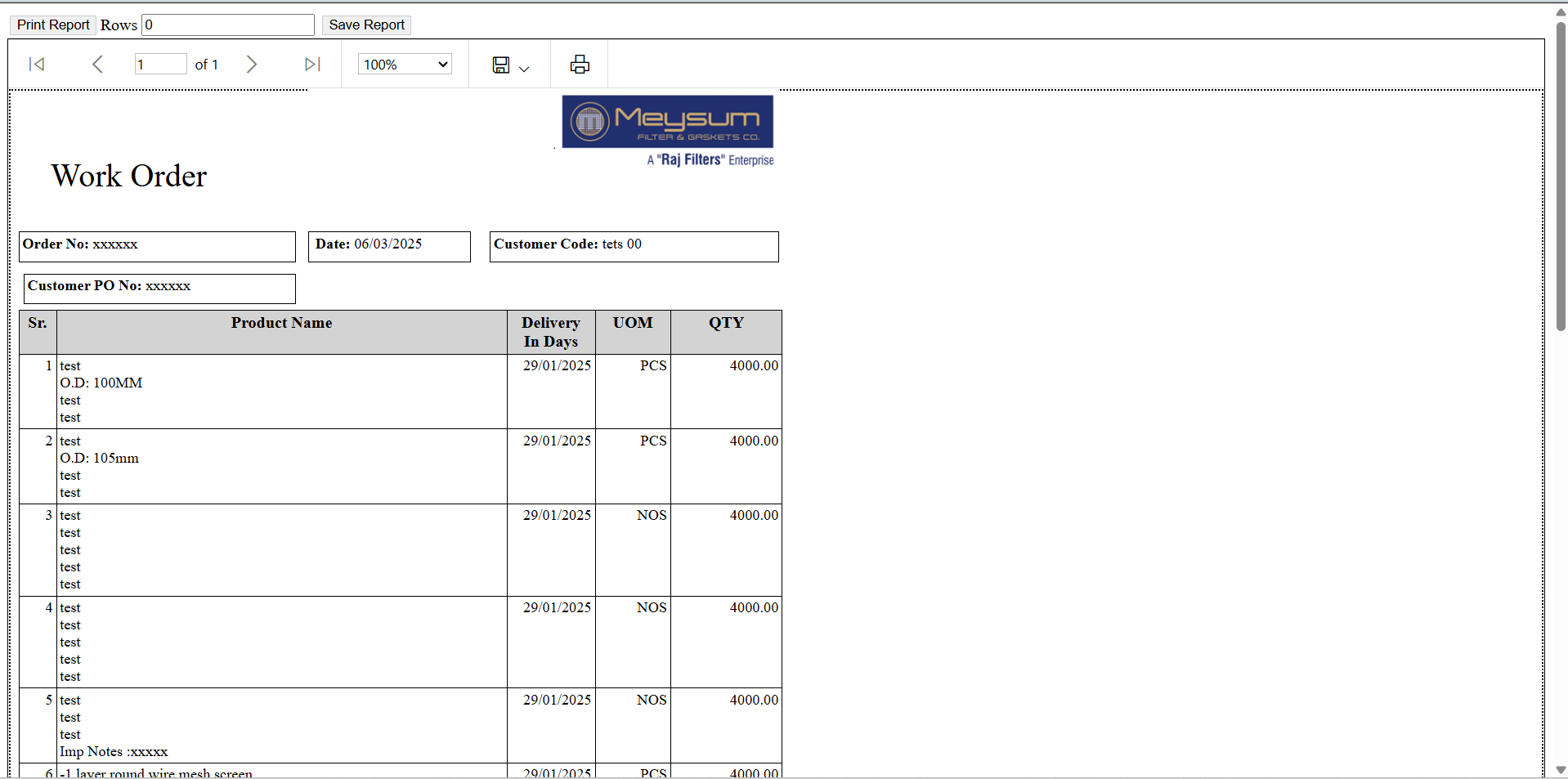

Work Order PrintERP

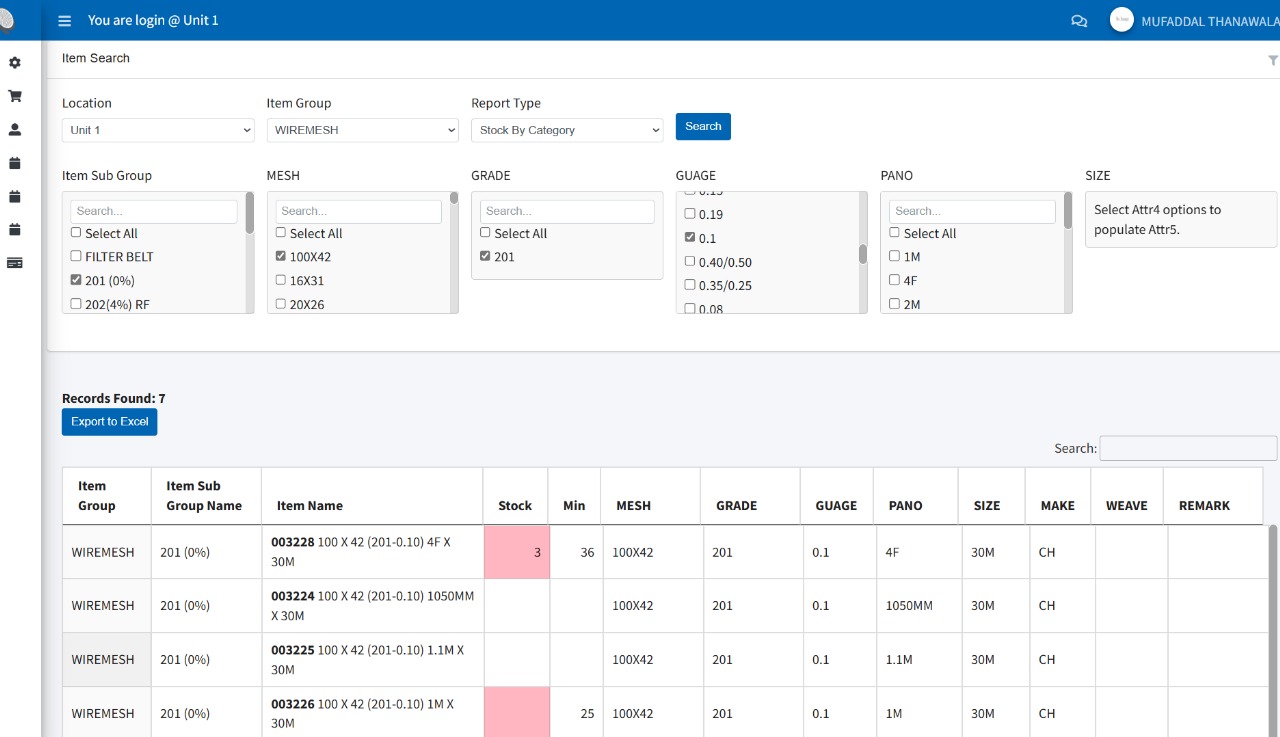

Stock SearchERP

ProductionERP

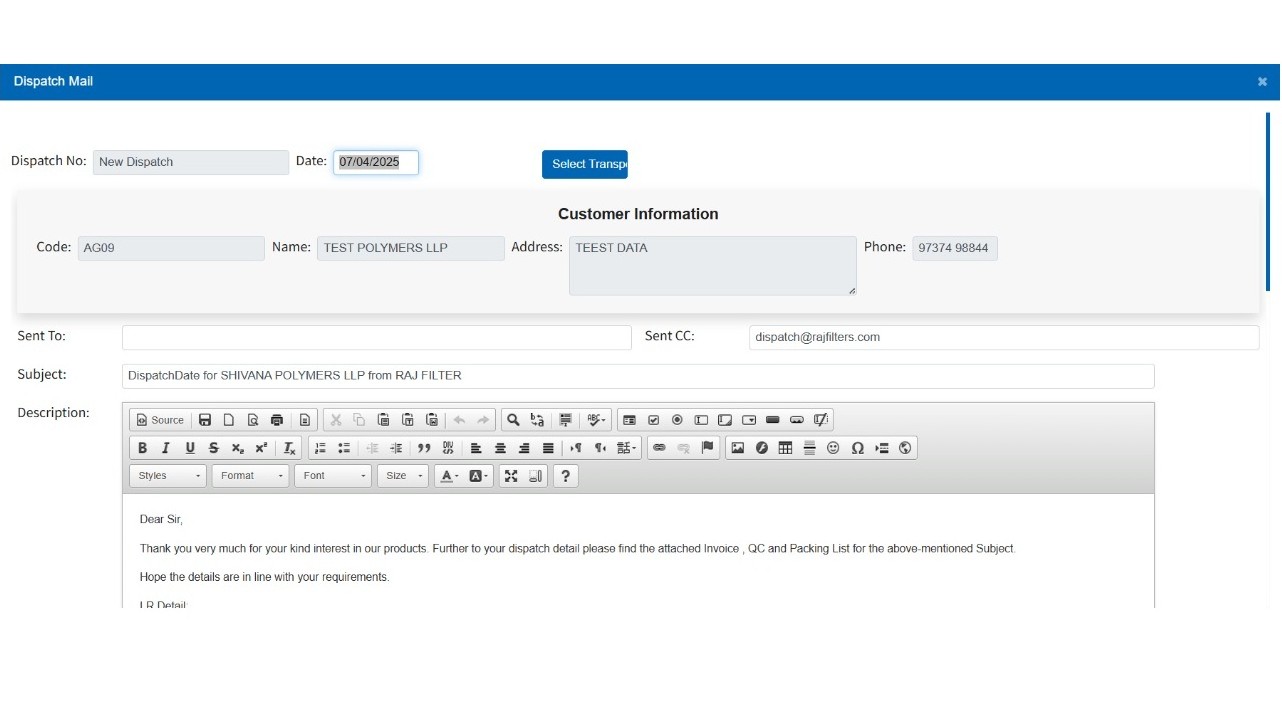

Dispatch_MailERP

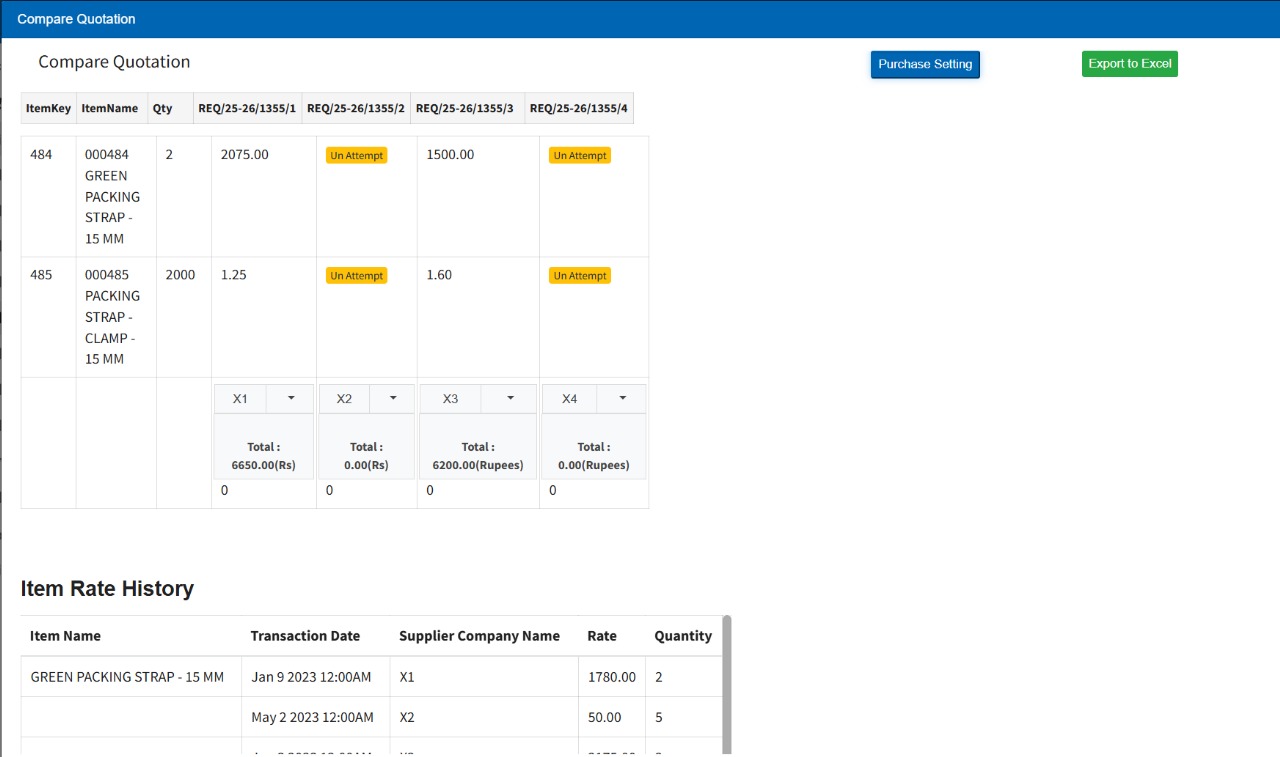

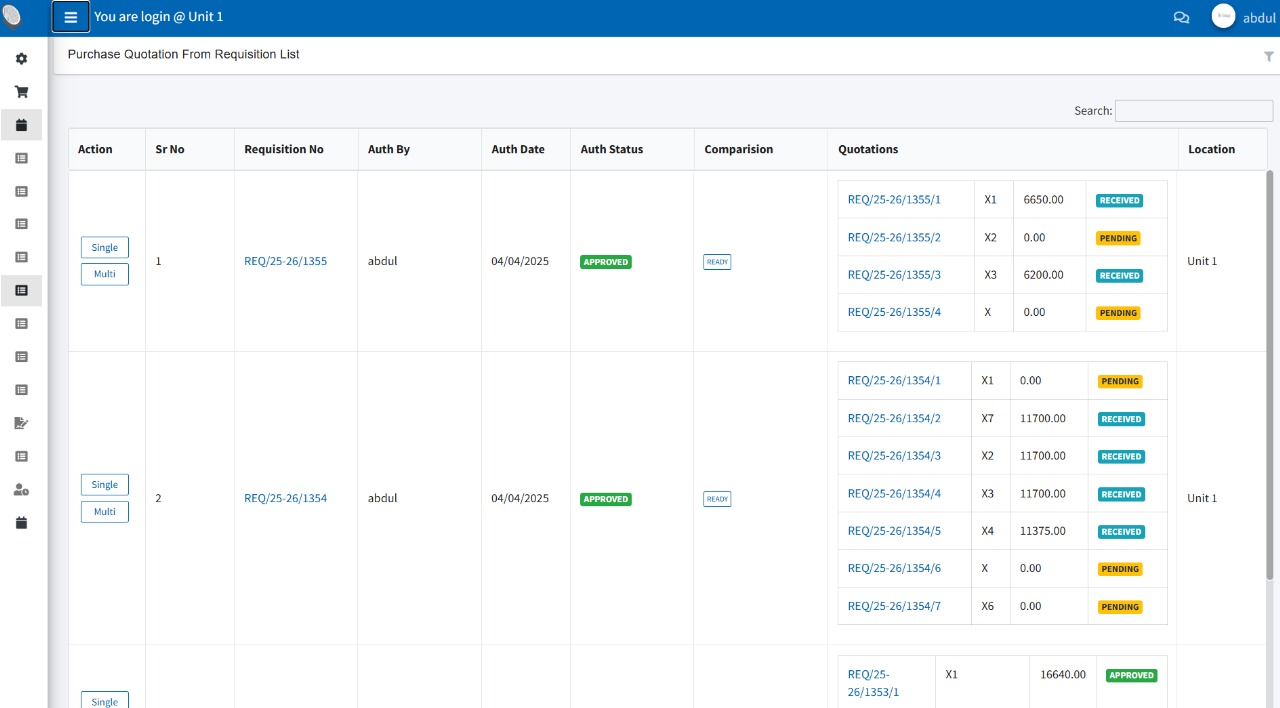

Quotation Receive EntryERP